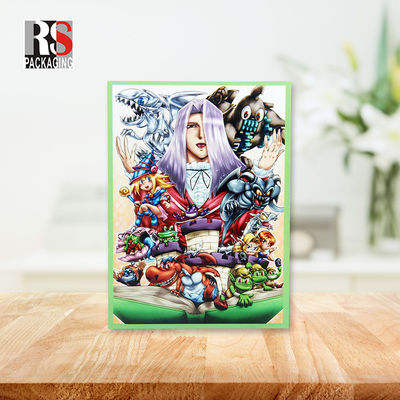

Ultra Pro Plastic Poly OPP Card Sleeves Protect Your Custom Box Trading Cards

Product Details:

| Place of Origin: | Guangdong, China |

| Brand Name: | Runsheng |

| Model Number: | game card sleeves |

Payment & Shipping Terms:

| Minimum Order Quantity: | 10000 pieces |

|---|---|

| Price: | $0.04/pieces 10000-99999 pieces |

| Packaging Details: | Carton |

| Supply Ability: | 30000 Piece/Pieces per Day |

|

Detail Information |

|||

| Surface Handling: | Hot Stamping | Industrial Use: | Gift & Craft |

|---|---|---|---|

| Use: | Other Gift & Craft | Material Structure: | Opp |

| Bag Type: | Flat Pocket | Custom Order: | Accept |

| Feature: | Recyclable, Waterproof Shockproof Dustproof | Plastic Type: | PP |

| Product Name: | Custom Printer Manufacturers Gift Yugioh Photo Card Sleeves | Usage: | Sport Card |

| Logo: | Accept Customized Logo | Size: | Standard Size |

| Function: | Protective Sleeves | Series: | Card Protector Sleeves |

| Keywords: | Custom Card Sleeves | Color: | Clear Or Customized |

| Application: | Card Gaming Supplies | Port: | FOB Shenzhen |

| Highlight: | OPP Card Sleeves,Ultra Pro Plastic Card Sleeves |

||

Product Description

Product Features

Applicable Range

|

Item name

|

custom box trading card game card sleeves protector ultra pro plastic poly opp yugioh anime matte tcg board game card sleeves

|

|

HS code

|

3923290000

|

|

Size

|

According to your requirements Customized

|

|

Material

|

PP(polypropylene) / VMPET(polyester) / laminated material

|

|

Color

|

Gravure printing 1-8 colors

|

|

Application notes

|

Imported high transparent CPP material, CPP material imported color matte, bright and smooth, feel good

|

The manufacturing process of game card sleeves can vary depending on the manufacturer, materials and design. The following is an overview of the production process of general game card sets:

1. Material preparation: First, the materials for making the game card sleeve are prepared. Common materials include plastic materials such as polyvinyl chloride (PVC) and polypropylene (PP). These materials are usually supplied in rolls or sheets.

2. Cutting: Depending on the required size and shape, the ferrule manufacturer will use cutting tools, such as a die cutter or laser cutter, to cut the plastic material into appropriately sized pieces. These pieces will form the basis of a single game card sleeve.

3. Embossing and Printing: Some game card sleeves may have embossed or printed decorative effects. This can be achieved by using heat pressing technology or a printing press on the plastic sheet. Embossing can add texture, pattern or logo, while printing can add color, image or logo to the card sleeve.

4. Folding and welding: Fold the plastic sheet into the shape of the card sleeve according to the design. Typically, two or more pieces of plastic are welded together to form the bottom and sides of the ferrule. Welding usually uses heat or ultrasonic technology to ensure the ferrule is secure and sealed.

5. Inspection and Packaging: The produced game card sleeves will undergo quality inspection to ensure that they meet specifications and requirements. They are then packaged into sets or packs and ready for delivery to distributors or end users.